The gas temperature drops significantly when pressure is reduced for gas turbine consumption. This Joule-Thomson-effect is countered by heating up the gas prior to pressure let-down, and prevents liquid dropout from the gas if one of the components passes below its dew point. strategically located sensors and switches monitor the design temperature, water level and pressure, safeguarding the entire system.

Any additional results of a risk assessment/hazard and operability study (Hazop) can be implemented in the control philosophy for each project section.

There’s a choice of heating methods:

- Gas fired indirect Water Bath Heater

– pressurized

– atmospheric

– nitrogen blanketed

– with retractable fire bundle (as per API 12K)

– water or oil for heat transfer medium

– with an internal bypass valve that allows very responsive gas temperature control - Gas fired Boiler + shell&tube heat exchanger

- Electrical heater

- Package can be supplied in a custom built vented container, free standing under a shelter or located in an adjacent building.

EASIER

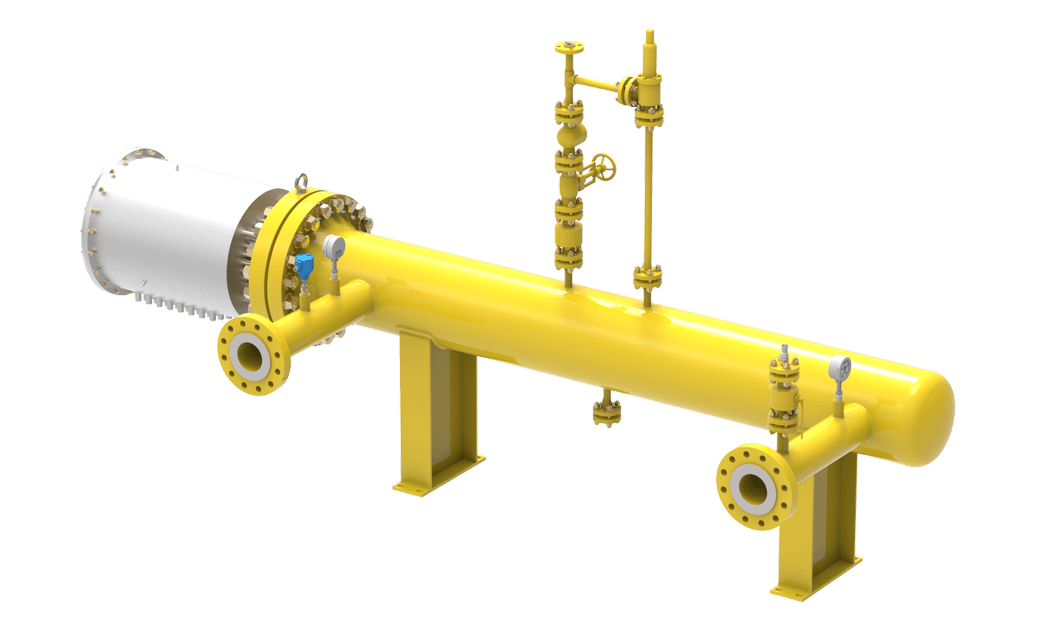

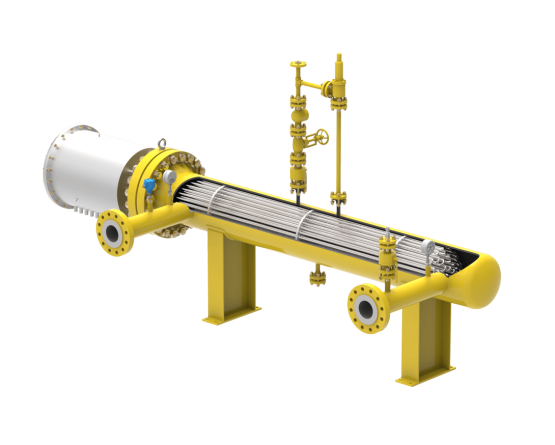

Water bath heaters are the most popular systems, with the natural gas being fed through a high-pressure tube bundle in a gas heated hot water vessel.

The heaters have a robust, low-maintenance design with a by-pass valve for temperature regulation. The forced draft burner is hinged for easy access to internal parts, the fire bundle can be made retractable for easy inspection and maintenance, and there’s easy access to manhole and instruments.

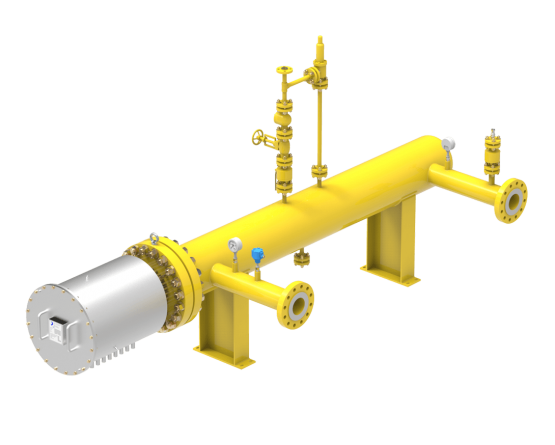

Boilers & heat exchangers (B&HE) also have a hinged gas-fired burner for easy inspection and maintenance. The large container doors allow full access to boiler parts. Piping and cabling is routed overhead to allow sufficient walking space, and all components can be isolated from the main system for draining and maintenance.

Electrical heaters heat the natural gas directly by heating elements. An external thyristor controller, either in a cabinet in the field or in the control room can regulate temperatures. Strategically placed temperature sensing elements ensure safe operation.

SMARTER

The water-bath heater’s thermal design has been optimized using thermal imaging and state-of-the-art software.

It has an integrated burner management system, and is even suitable for desert climates. A nitrogen blanketed water basin prevents internal corrosion. An internal gas bypass valve gives extremely accurate and fast temperature control. The heater has a dedicated single or redundant burner gas supply system, and gas piping is routed to allow easy access to retractable bundles.

The boiler and heat exchanger can have a single or multiple cascade boiler system with single or redundant hot water pump. Boiler and pumps can be containerized to shield them from ambient conditions, or installed in a building. Various methods can ensure proper heat distribution on switchover.

Electrical heaters can quickly vary the heat input for accurate temperature control. These types are often used for start-up heating. Various input voltages are possible for different power sources.

BETTER

The high-capacity closed-loop heaters are efficient. Smart design implements proven technologies and helps you reduce the CAPEX and OPEX costs. Each heater undergoes extensive quality checks before they leave the factory, including a leak test.

Case studies

Short 32-week turnaround time

Fuel gas inlet station for power plants

- What did our customer request?

-

This project was part of an agreement between Siemens and the Egyptian government to add 50% more energy to the power grid within a number of years. We were asked to supply the Fuel Gas Conditioning Station for three of the prospective power plants (Beni Suef, Burullus and New Capital). After completion in May 2018, the three power stations will be the largest gas-fired, combined cycle power plants ever built and operated in the world. And they will supply enough electricity for 45 million people.

- Our solution

-

Petrogas delivered the fuel gas systems for the 24 H-Class gas turbines, designing, engineering and fabricating the system sections. In particular, we developed a custom DRIP-barrel (horizontal liquid separator) and also supplied Emergency Shut-Down, inlet filters, electrical heaters and control cabinets.

- What set the project apart?

-

We usually build all the pressure vessels and pipes in our own workshop in Eindhoven, the Netherlands. Because of the size of the project, though, we outsourced part of the production to some of our expert subcontractors.

Together, we helped Siemens to set a new worldwide benchmark for the execution of a fast-track power generation project. After completion of the first phase Siemens was already able to connect 10% more power to the grid than forecast, a surplus sufficient to supply electricity to an additional one million people in Egypt.

- What were the project challenges?

-

“The short turnaround time was a real challenge. For a project like this it is usually 10 to 12 months, but we delivered the installation within 8 months. Siemens was delighted with the result and the plants actually achieved first-fire well ahead of schedule.”

- What did our customer request?

-

Cegelec needed more electric capacity at a petrochemical industrial complex on Das Island off the coast of Abu Dhabi. Petrogas was asked to supply the fuel gas conditioning units for the natural gas powered turbine generators. These units ensure that the gas arrives at the gas turbines under the right conditions.

- Our solution

-

The natural gas was being sourced from different locations, so there were differences in pressure, composition and temperature. Gas from one of the suppliers also had high acidity. Petrogas supplied the installation to filter and heat the gas and reduce the pressure.

- What set the project apart?

-

The limited amount of space on the island meant the installation had to be as compact as possible, while leaving enough room for operation and maintenance.

- What were the project challenges?

-

“Initially, the requirements for the fuel gas conditioning units were fairly basic. But as the project progressed, several new key design requirements became evident. We pride ourselves on our versatility, and responded quickly to incorporate all the additional demands.”

Dedication and hard work

Ras Al-Khair Power Plant (fuel gas system)

- What did our customer request?

-

The Saline Water Conversion Corporation is a Saudi Government Corporation responsible for producing electric power and desalinating seawater. The SWCC Ras Al Khair project was at the time the largest combined power and desalination plant in the world and won the prestigious “Desalination plant of the year” award in 2015. It is a landmark project for SWCC.

The plant converts more than 1 billion litres of seawater into potable water each day, transforming the potable water situation in Riyadh, one of the world’s fastest growing and most water-stressed cities. The plant also produces 2400 MWe of electricity for the Eastern Province of Saudi Arabia and helps to power the nearby Ma’aden/Alcoa Aluminium plant.

The power plant is gas & oil fired, and Petrogas won the contract for the fuel gas conditioning station with 1 million Nm3/h capacity for 12 gas turbines, along with the backup fuel oil system to ensure a high quality, reliable and continuous supply of fuel for the turbines. Waste heat and reverse osmosis are used to desalinate 1 billion litres of sea water per day. - Our solution

-

In close cooperation with the owners’ engineer Pöyry, we designed six identical blocks. Each had two mirrored gas conditioning systems including Emergency Shut-Down valves, filters, flow meters, heaters, pressure reducing systems for GTs and boilers, pressure boosting compressors and a high pressure gas buffer system. Petrogas built the skid-based system in workshops in the Netherlands and China, and erected and commissioned the system on site.

- What set the project apart?

-

Because Petrogas has both engineering and fabrication in-house, our customer benefitted from our practical experience in the initial basic design phase. The design was optimized before Petrogas built the skids, wrote the control software and performed the on-site commissioning.

The system can boost gas pressure for a prolonged period and can maintain gas supply for several minutes when the gas feed is interrupted to allow the turbines to switch to fuel oil. Petrogas played a substantial role in drawing up the operating philosophy between all these systems. - What were the project challenges?

-

“The sheer size of the project made it a challenge. The system is actually twelve complete 12” gas conditioning systems with 100% redundancy. The photo shows the stacks of the Water Bath Heaters, 36 in total.

Resources, planning, logistics between several workshops and dozens of suppliers all required a creative approach. The order came in 2011 when we already had a healthy backlog, and the order was worth about a year’s turnover. Petrogas successfully completed the job thanks to the dedication and hard work of our personnel and suppliers. “

- What did our customer request?

-

Our customer required a fuel gas conditioning station for the Al Diwaniya project. The station prepares and conditions the gas before it enters the turbine, ultimately to generate electricity. The conditioning entails filtering, heating and reducing the pressure.

- Our solution

-

Petrogas supplied the Fuel Gas Conditioning Station, including hardware and control systems. A fuel gas metering system measures the gas used, and a safety valve shuts down the gas supply in case of extreme pressures or temperatures.

- What set the project apart?

-

Petrogas also performed part of the overall engineering. From our experience in similar projects, we advised the customer to approach a number of things differently to improve safety and efficiency.

- What were the project challenges?

-

“Al Diwaniya is located around 250 km south of Baghdad, in a region with security risks. Thanks to our local network of qualified professionals we assembled and commissioned the system on site. An innovative design meant we could easily mount the skids against each other on site, leaving just the bolts and nuts to be tightened.”

Contact us

Would you like to discuss your project with our Experts? Please feel free to contact us.

Direct contact with our Experts

Your interest

Heating