EASIER

Petrogas biogas conditioning systems are designed to remove the harmful elements while maintaining a consistent flow, pressure, quality and temperature of the biogas stream.

Biogas production is dependent on the varying organic loadings and temperatures of the anaerobic digestion (AD) system. We take care of all necessary steps to prepare to gas for use, from initial design of the most effective system al the way up to the final commissioning on site.

SMARTER

By thoroughly sampling and testing the biogas stream we determine the characteristics of the contaminants present, on the basis of the gas composition data – and your project specific requirements – we define the optimal process design for your biogas conditioning system.

We take local air pollution, odor regulations, and the potential use for the biogas into account. At the hand of this information the type of conditioning technology best suited for your application can be determined. A preliminary engineering study will be performed to identify the most cost-effective approach to successfully condition your biogas stream.

BETTER

Petrogas Biogas Conditioning systems are designed to offer the most cost-effective solution for the protection of downstream equipment, like combustion turbines and engines, agaist the damaging effects of siloxanes and other volatile organic compounds (VOC’s) in sewage, digester or landfill gas.

Landfill gas and Sewage gas, in particular, contain varying quantities of water, siloxanes and volatile organic compounds (VOC’s).

Unless these contaminants are removed from the biogas there is a significant risk to damage downstream equipment during combustion.

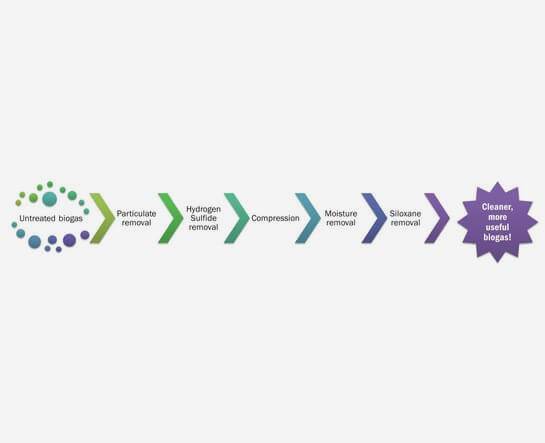

System sections

Particulate Removal

Particulate removal is essential to protecting sensitive equipment downstream. A mesh gas filter with a pore size of 3 to 6 microns disperses the gas stream, causing any fine particulates to drop out.

Moisture Removal

Moisture removal is accomplished by utilizing a gas-to-liquid heat exchanger that is cooled by a remotely installed chilling system. The gas temperature is reduced below the dew point as it passes through the heat exchanger, causing moisture to precipitate.

Alternatively we can apply glycol dehydration to remove the water particles from the gas.

H2S Removal

Even though the composition of biogas varies depending on the nature of the AD feedstock used, in general it contains moderate to high levels of hydrogen sulfide or siloxanes. Hydrogen sulfide levels below 300 ppm are typically not an issue for the desired end use of the biogas; however, local air regulations may necessitate its treatment. The wide variety of hydrogen sulfide removal systems can be grouped into three general categories:

- Media based

- Biological

- Chemical

Siloxanes are chemical compounds made of silicon and oxygen and are found in a variety of products ranging from personal care (e.g., hair shampoo) to lubricants and paints. Consequently, siloxanes can be found in the wastewater from industries making these products.

Our main concern is the presence of siloxanes in waste biosolids from public treatment plants, due to the use of cosmetics. The Siloxanes must be removed from biogas to realize long-term economic benefits.

- The most frequently applied technologies are:

- Activated carbon adsorption

- Activated alumina absorption

- Synthetic resin absorption

- Absorption by selective liquids

- Membrane technology

As a result, the sampling and testing of biogas for siloxanes is an important step in biogas upgrading process.

Compression

Particulate and moisture removal and compression systems are typically packaged into a single skid since all biogas conditioning systems require them. Compression is generally required to meet the required pressure for use or transportation.

Contact us

Would you like to discuss your project with our Experts? Please feel free to contact us.

Direct contact with our Experts

Your interest

Biogas Conditioning