The final run consists of a series of equipment that form the last line of defense to protect the Gas Turbine from foreign material. Its components may include consumption flow metering, performance heating, filtering and a shutoff valve section.

EASIER

The consumption flow metering section is similar to the main metering system, but is used for efficiency monitoring of the gas turbine.

The same types of meter can be used, and connected to a local field control cabinet that communicates with the main control system through ethernet or fiber-optic cable.

SMARTER

The performance heater uses waste heat from the gas turbine flue gas heat recovery system to heat the gas before combustion to increase GT efficiency.

The heat exchangers can be straight, U-type shell&tube, or printed circuit type. An electric heater can optionally be added to heat the gas in simple cycle mode or under startup conditions.

BETTER

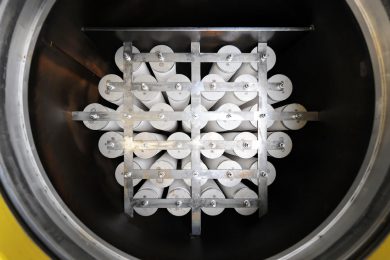

The final filter removes any foreign material (e.g. construction debris) trapped in the interconnecting piping at the power plant.

Contact us

Would you like to discuss your project with our Experts? Please feel free to contact us.

Direct contact with our Experts

Your interest

Final Run